Providing Solutions of Magnetic Fixing to Precast Concrete Industry

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

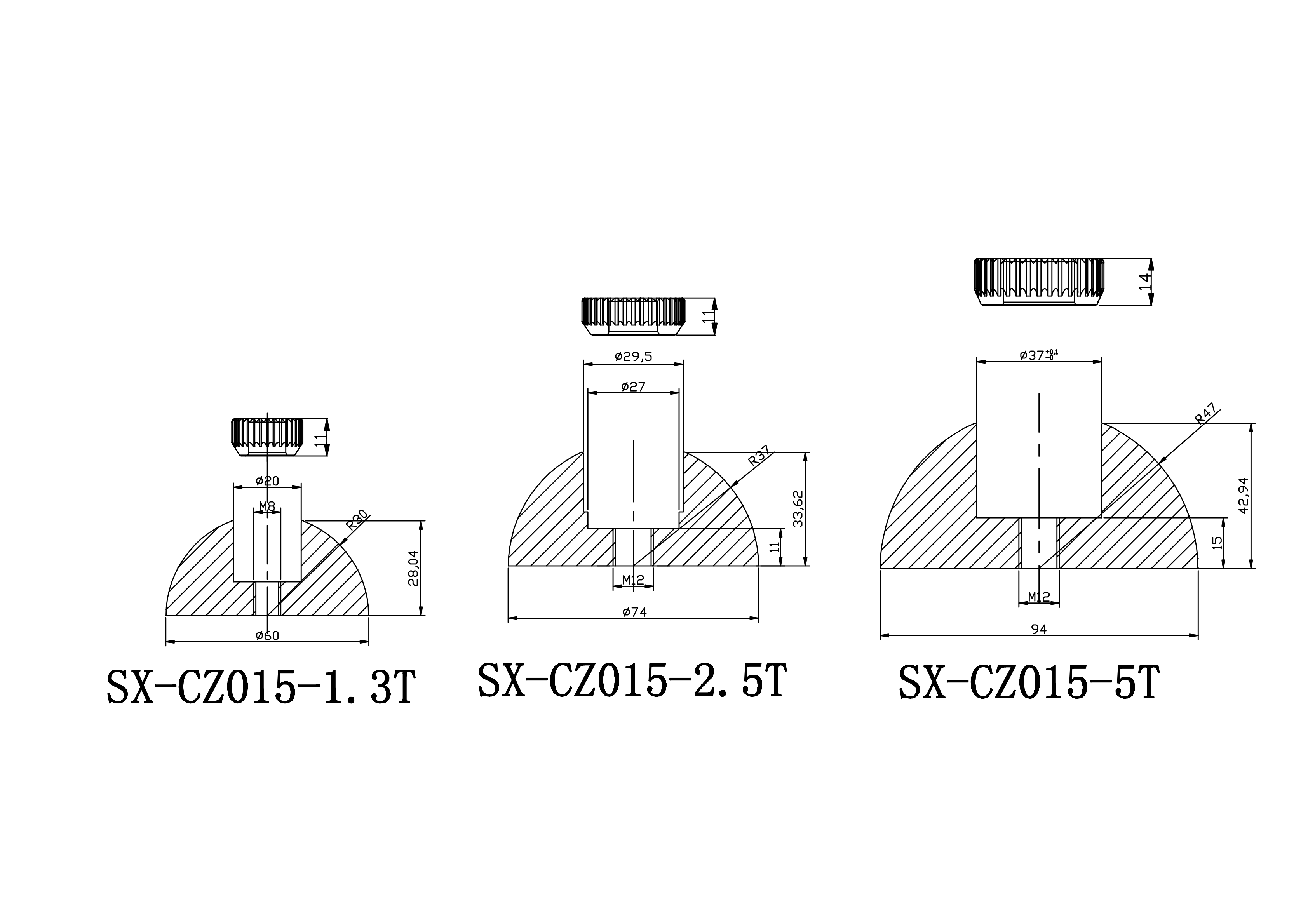

SX-CZ015

24pcs for one carton

30days

SAIXIN

magnet+iron

160kgs

0.70kg

color zinc-plated

1-3 years

Product Description

SX-CZ015 Series is machined from iron material and fitted with high performance magnets, providing a high

power system for securing ball-head lifting Anchors. The magnetic surface is sealed, protecting it against corrosion and damages.

Requires use of rubber seals to stabilize anchor.

1.3T,2.5T & 5T are available. We also can produce as per your requests.

SAIXIN insert magnets series are designed and developed for various embedded parts of precast concrete. During precast concrete production process, we need to embed various switch holes, pile holes and connection or lifting sockets. Using SAIXIN insert magnets to fix the embedded parts, magnets secure the parts against sliding and slipping. Our product are durable, cost-saving, easy-to-use and efficient.

Instruction

SAIXIN® insert magnet is made of permanent neodymium magnets, combining with steel, rubber or nylon can be made almost any shape to fix embedded part in precast concrete production.

As using, the magnetic surface fix on the platform or steel shuttering, another side fix the embedded part, because of the high suction force, the embedded part can stay accurately in the precast concrete element.

SAIXIN ® series insert magnets products with the advanced magnet protection system, can effectively protect the magnet from corrosion from outside material, improve the abrasion resistance, then improve the service life of the magnet.

Maintenance And Safety Guidelines

(1) In order to avoid the insert magnet damaging, do not crash and use hard tools to knock it.

(2) The touching surface should be kept clean and smooth.

(3) After using, clean the insert magnets. Max working and storage temperature should be below 80℃,and no corrosive medium around.